Beyond Destruction: Insight Ultrasonics' Mission to Reinvent Weld Testing

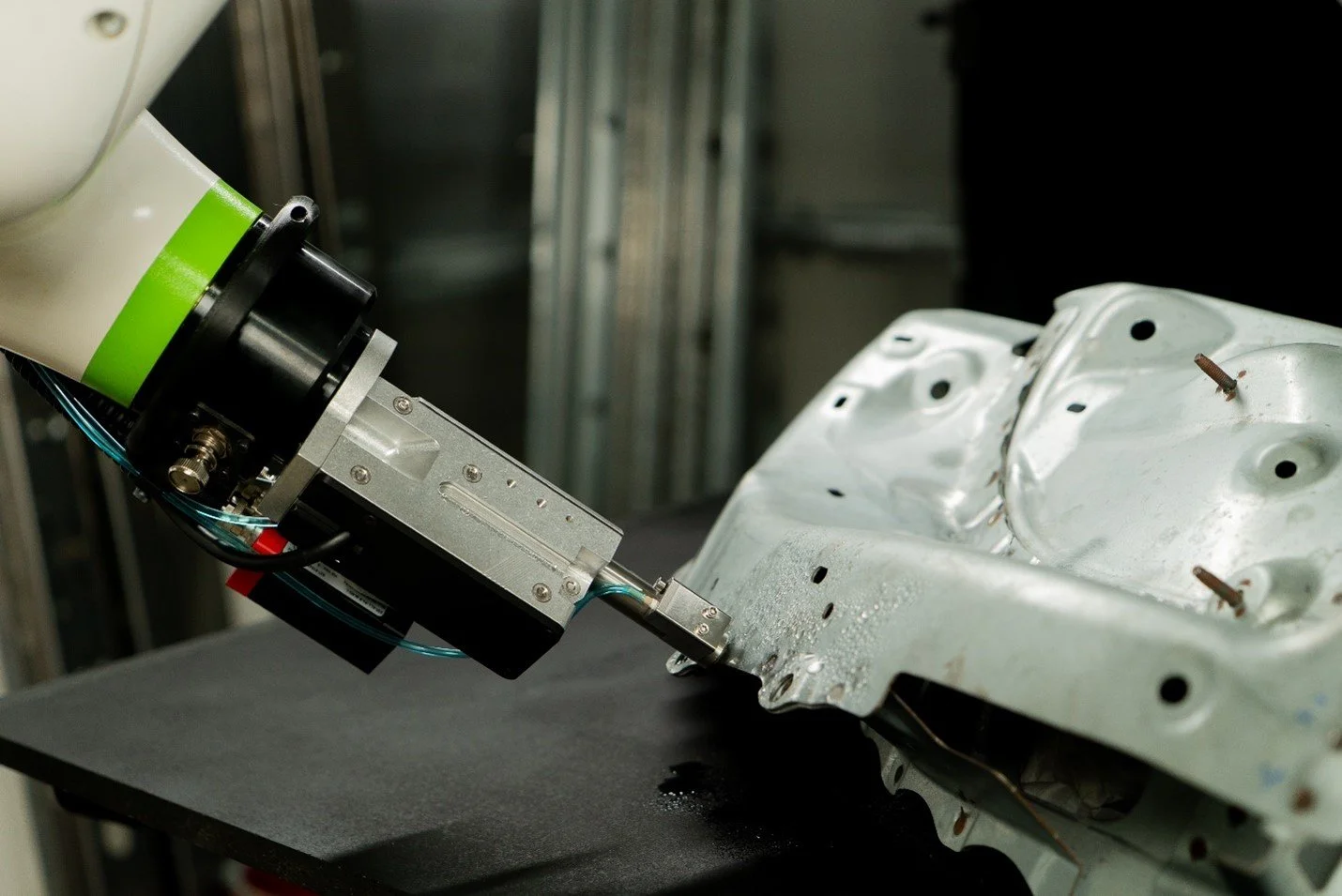

Pictured: The Insight Ultrasonics product measuring the quality of a spot weld on a metal component

Founded with a vision to eliminate the waste and risk of traditional labor-based spot weld testing, Insight Ultrasonics is quietly revolutionizing one of the most overlooked, yet critical steps in global manufacturing of weld validation.

Insight Ultrasonics’ mission is simple, yet powerful: replace destructive weld testing with automated, non-destructive advanced solutions that create safer environments and more efficient processes.

Globally, destructive testing of spot pot welded components in just the automative markets is estimated at $2.5 billion; however, this figure does not account for associated risks, including worker safety concerns, inefficiencies, and unsustainable practices. Traditional destructive testing requires manual labor of physically pulling apart welded components and measuring the spot welds with calipers for quality test, often destroying valuable materials, risking technician safety and delaying production. This is where Insight Ultrasonics offers a better way.

Engineering Safety Through Sound

Insight Ultrasonics’ core technology is rooted in ultrasonics validation, built to ensure structural integrity without damaging the product in any way. Here, instead of pulling a weld apart for sample testing, manufacturers can now validate the process in real time with precision and confidence.

According to the internal data, companies using Insight Ultrasonics’ products could save from 50-70% in spot weld testing costs along with improving labor safety, process traceability with automation.

In 2024, Insight Ultrasonics joined the Warehouse Business Accelerator Hub (WBA), a practical decision that proved to be strategic. The WBA offered not only an affordable lease option, but also an ecosystem of like-minded innovators solving real-world problems under one roof fostering collaboration.

The WBA has fostered unexpected collaboration for Insight Ultrasonic. One such example: a partnership with Better Process, a fellow warehouse automation company, whose founder has since taken on the role of CTO at Insight Ultrasonics. This collaboration has allowed Insight to access automation engineering expertise and hands-on support without traditional payroll structure. Today, Insight Ultrasonics operates efficiently with no paid full-time employees, instead outsourcing development to Better Process’s talented team, creating a flexible and cost-effective business model.

Milestones & Momentum: From Prototype to Production

A major milestone came when Insight Ultrasonics signed its lead customer: Shspe Corporation, a Tier 1 supplier to automotive OEMs. This partnership is more than just a sales win—it’s a co-development opportunity to fine-tune Insight’s technology for real-world applications. The milestone also includes earned approval from a major OEM, with two additional automotive OEMs currently evaluating the technology. As Insight iterates and improves its processes, it remains focused on the most pressing customer pain points: worker safety, automation effectiveness, cost-efficiency, and scalable performance in manufacturing.

Looking Ahead: Building a safer Industrial World

As industry standards evolve and automation becomes vital, Insight Ultrasonics is positioned to lead a shift toward safer, smarter and more sustainable manufacturing via advanced non-destructive solutions for spot weld testing processes.

Stay connected as Insight Ultrasonic continues to scale, innovate and drive the next wave of ultrasonic testing solutions.